CIRC

Work related project | Team project

Case study | Circular Design

”What if we could design a CIRCULAR SCREWDRIVER?”

This was a case study that I worked on at INDEED Innovation. The study focuses on how to make small consumer electronics as circular and sustainable as possible.

Main Team | Rebecka Rosenlind, Johanna Königsberger, Maxime Wiquart, Felipe Maffezzoli, Jonas Krüger, Siguang Ma, Alex Dumler

My work | Under guidance of Johanna as project manager I was in charge of this project. I developed and explored all the circular and sustainable design principles, methods and strategies. I worked thoroughly with research, ideation, CAD exploration, prototyping, video editing, user experience as well as making circular and sustainable design decisions (from the inside out).

Background

There are endless products in the field of small consumer electronics that are already on the market and that are added every day. Whether it‘s a cordless screwdriver, a flashlight, a sex toy, or an electric toothbrush. They all have a similar setup: battery, motor, cable, PCB, charging unit, a small (light) indication, often plastic housing, etc. And they all have one thing in common: The devices are not built to be repaired. Once a part is broken, they go into the trash, resulting in substantial e-waste. Only 20% of the around 50 million tons of e-waste produced each year is formally recycled, revealing the unsustainable nature of current production and consumption methods. But with things such as the right to repair movement and consumers becoming more aware of the topics of sustainability and circularity, the market is starting to change. CIRC is a case study made to show how circular design principles could be implemented to limit e-waste, save resources, and enable reparability at scale.

FROM LINEAR TO CIRCULAR

Linear screwdriver system map

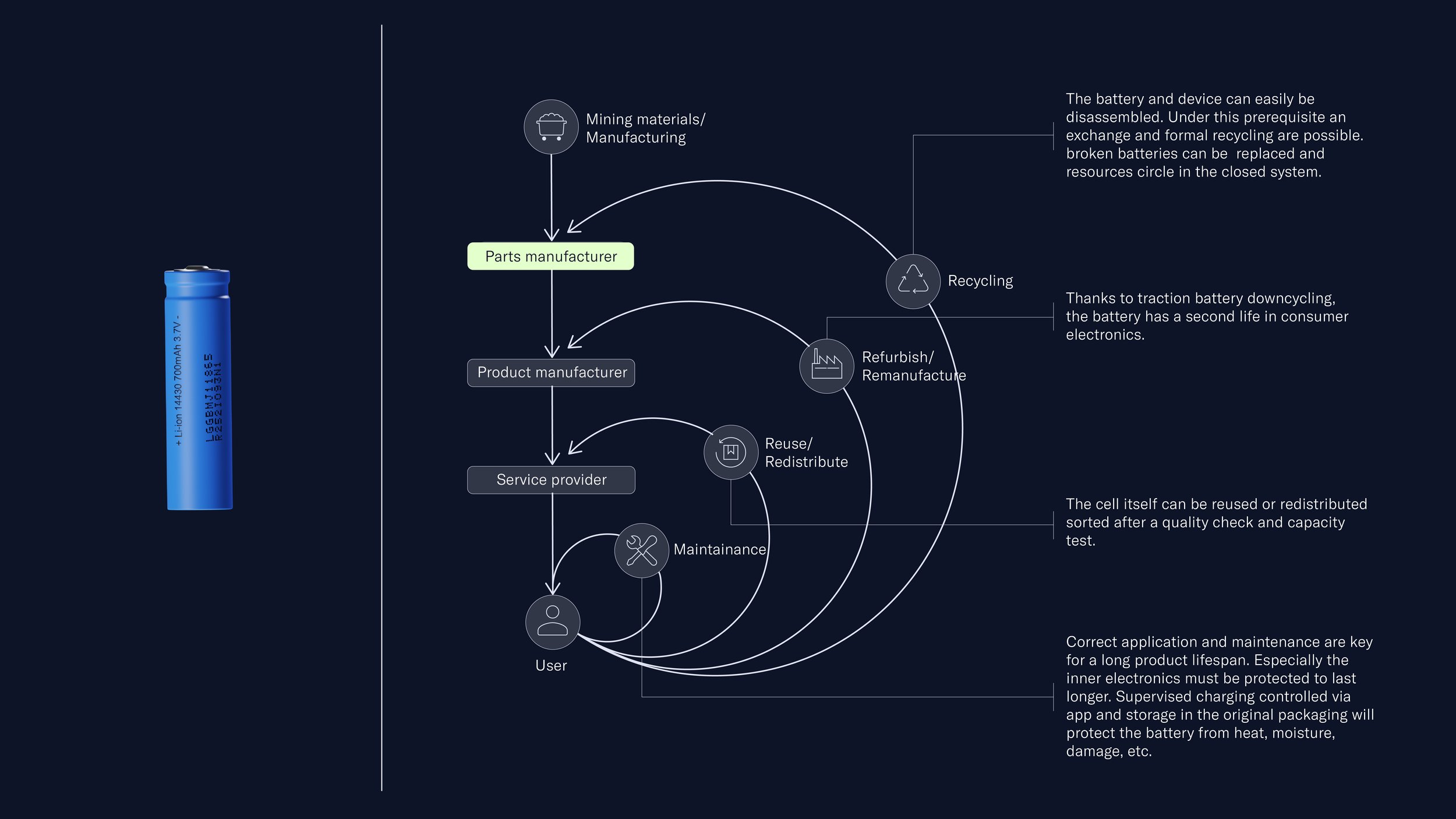

Circular screwdriver system map

Circular economy | A circular economy is fundamentally different from a linear economy. Simply put, in a linear economy your company mines raw materials that you process into a product that is thrown away after use. In a circular economy, you close the cycles of all these raw materials. Waste does not exist in a circular economy and products, as well as raw materials, are designed to be reused as long and intensively as possible. “Take, make, waste” is our current economic model. It is characterized by a linear, usually limited product lifecycle. For example: If your current screwdriver breaks or becomes outdated, you just buy a new one. You might keep the old one in your drawer for some time, but unfortunately, these goods will end up in a landfill one day. Even in countries with a functional recycling system, informal disposal, and the over proportional growth of e-waste bear challenging problems. Policies and established infrastructure buffer the negative effects in the west. But in less-developed countries, e-waste has added challenges to the already existing waste-management crisis. What if we tackle the problem by its source?

The circular economy eliminates waste. It is a response to the inefficient management of the resources in the traditional linear model. By rethinking the system and value chain from the beginning, strategies like reduction, reuse, and recycling are incorporated by design into the product and its lifecycle.

Circular strategies

Technical side of the butterfly diagram | Part level

Technical side of the butterfly diagram | Product level

Circular Strategies | The R-ladder of circularity strategies is fueled by innovation in product & service design, technology, and business models. The largest environmental benefits are obtained if resource-reduction innovations are considered early in the production chain. And waste disposal and incineration without energy recovery are avoided where possible.

Some of the main circular and sustainable strategies and methods that I have applied to this concept has been following:

R-strategies

Material and sourcing

Sustainable components

Design for disassembly

Disassembly mapping

Right to repair

Local production

Circular supply chain

Waste reduction

Butterfly diagram

design challenges

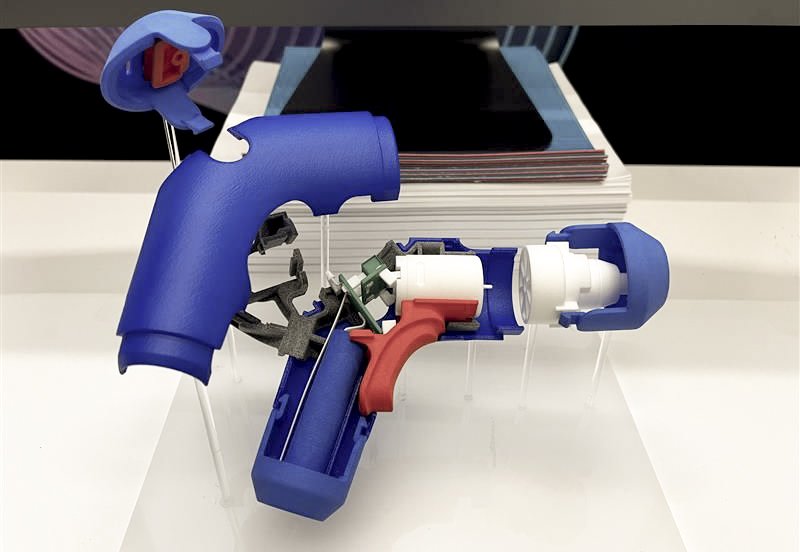

This projects main aim was to redesign an everyday object such as an consumer electronic and to make it fully circular and as ideal as possible. In the process, I looked a lot into to intuitive design, broadening the scope, in order to ease the repair for users as well as technicians. Under this premise, each step should be accessible for everyone, The screwdriver is a cheap tool that many households own in order to fix and adjust things at home. I worked a lot on the products architecture, all from inner components to outer parts, redesigning it completely to fit the main aim of a circular product. Shifting the focus from efficiency to usability and reparability broadened the industrial design perspective, creating room for innovation.

I also created a disassembly map to be able to further develop and improve the product. In this way it was easy for me to see how to access certain components as well as spotting potential hot spots (e.g. a step that takes a lot of time, precision, force, extra tools needed). In the redesign process the focus was to realize fewer steps and materials. The lesser time and tools needed for the user the better, such as for repair, remanufacturing, and recycling.

I did a lot of research in order to find the ideal solution/answer for each part and component. Some components where easier than others to find a good alternative for, but for those parts without any ideal solution as of today nor upcoming technology, I chose parts with the most potential to head in a sustainable and circular direction. I also looked a lot into circular and sustainable materials for each component fulfilling all security values, ergonomic obligations, and design statements.

Material choice

Circular and sustainable components

Materials | rPET stands for recycled polyethylene tetraphyte (PET). PET is the world’s fourth most common plastic resin. You find it in clothing, food packaging, etc. The outer shell and inlay for CIRC are made from injection-molded rPET which comes from a recycled, pre-existing source. To produce our CIRC, we take plastic that has already been created, ensuring that this material doesn’t contribute to landfills. Furthermore, it is possible to save up to 50% more energy this way compared to producing normal PET from scratch as a virgin material. If any of the parts that are made out of rPET breaks it will be made into pellets that can be used to 3D print and/or mold new parts. Injection molding is recommended to produce at scale, while 3D printing enables local production and limits the CO2 footprint for repair or extension parts.

Stainless steel is almost 100% recyclable at the end of life. Therefor this material is used a lot for the inner components such as the chuck or the motor. When any of these components breaks, it will be sent back to the business owner, who makes sure it’s recycled or recovered to produce new components. During recycling, it is separated as metal scrap parts and melted to be re-casted and re-purposed.

CONCEPT IDEA

Designed for disassembly

Intuitive design, form, color and details indicating functions

Battery icon indicating where battery is located

Inlay part, designed to keep inner components intact and for intuitive and easy disassembly

Smart numbering for guidance

Color coding on inner electronics for guidance

Circular Screwdriver | To ensure intuitive accessibility, all possible friction was limited. I worked a lot on developing a clear and intuitive product through clear color coding, transparent architecture, and numbering of components to guide the user, making them willing to repair, reuse, revamp, or recycle the screwdriver. Recognized vulnerabilities related to recycling or reparability were eliminated in the design process. Reduced complexity of materials by reducing the number of materials allows high efficiency in sourcing and production, without having to sacrifice on ergonomics or safety. Instead of layering the components in glue and rendering them inaccessible for repair, reuse, or recycling the design was stripped down to its most fundamental necessities, creating a timeless and minimalistic aesthetic. The screwdriver has been designed so it can be opened up and disassembled all by hand, no screwing or soldering needed, which saves a lot of time and effort. The smart numbering guides that I developed helps the inexperienced user/first time user and always ensures success for maintenance and disassembly.

Packaging

Packaging | To enhance the durability of the inner and outer parts, packaging becomes key. Originally supposed to be out-designed, our assumptions where revised and the packaging ended up as a durable outer case. In this way, the packaging protects the product from heat, moisture, impact or damage. Next to this functionality, it allows wider branding and communication areas. For example, for a QR-Code leading to registration and further instructions via app/website/digital content. To reduce the CO2 impact during shipping, the size of the packaging was reduced to the bare minimum. Since most people already have this at home, it comes without a usb-c charging cable.

Digital platform

User interface | This project focused both on the business owner as well as the user/consumer. On one hand there is the business owner, they can get a hold of and source benefits from the asset dashboard to see material flows, cash backs, and system synergies between partners. On the other hand the consumer is empowered via the app to participate in the sustainable system in an intuitive way.

The digital infrastructure connects the analog product (wherever it is) with the business model and its stakeholders. It is the representation of the thought through reparability and ensures that the product keeps its functionality and value while in use and aging. This is a paradigm shift making the business future-proof. Connected products makes lifetime support feasible and will integrate professional servicing as well as recycling capabilities.

As an example, the system is designed to scale and interconnect all stakeholders for not just one but several products and value streams. With a corresponding digital infrastructure, many reservations can be removed. The user/consumer will be educated, tracked, and encouraged to do as wished. The product performance and maintenance can be controlled and pro-actively optimized. The supply chain is well managed by numbers and insights, while product and marketing management better understand their target. The business owner and all participants of the closed-loop system can coordinate their efforts and even harvest or sell the data collected.

CIRCULARITY SHOWCASE

Fab City Hamburg | The Future of Making Conference

Open House, Newlab, NYC | Circular design exhibition

Circularity showcase | The Circular screwdriver has been utilized for multiple events, talks and exhibitions revolving sustainability, circularity and the circular economy. It has been presented as an ideal example of what direction we as designers should be heading. It showcases how circularity can be implemented directly on a product design level, including the physical product, digital platform as well as system behind with the whole supply chain involved.

Some examples of where the circular screwdriver has been presented so far:

Fab City Hamburg, The Future of Making Conference | Germany

Museum workshop, Hamburg | Germany

Vitra learning workshop, Hamburg | Germany

Open House, Newlab, NYC, Circular design exhibition | USA

IDSA NYC | USA

Circularity 2022, Atlanta | USA

Design Beijing | China